When you think of a construction environment that fosters positive relationships and maximizes productivity, what seems more fitting? Is it:

- Secretive attitudes, protective measures, proprietary turf wars, mistrust and grudging communication where necessary–if at all?

- Open minds, respect for others, responsibility taking, friendly sharing of ideas and processes and ongoing communication geared toward all-around project success?

If you guessed the first one, we could probably assume two things: You’ve been in construction too long, and you might not be giving new project delivery methods like design-build enough credit.

Nevertheless, design-build is one of the most progressive methods of project delivery and is quickly becoming an industry standard. If you want to experience faster project completion times, more reliable budget estimates and a better brand overall, it’s time you consider embracing this approach as well.

How? Here, we’ll discuss the ins and outs of working more collaboratively through this up and coming delivery method.

Design-Build: Quickly Overtaking Antiquated Design-Bid-Build

Previously thought of as the project “alternative method,” design-build is quickly becoming a project standard for delivery. In fact, according to Construction Dive, it’s expected that design-build will deliver almost half of U.S. projects by 2021, with design-build construction spending in the assessed segments anticipated to grow 18% from 2018 to 2021 and reach more than $320 billion.

One of the reasons for its wider-spread adoption is state legislation in favor of it. “Last year, for example, Virginia legislators expanded design-build authority to all local governments,” explains Construction Dive. Plus, “the New York governor’s budget added new state entities to the list of those authorized to use design-build and the Washington state legislature recommended design-build for construction of a bridge.”

With the increase in state and local government backing, it’s no surprise that 43 states now have full or widely permitted authorization to utilize design-build for public agency projects. As such, it is quickly overtaking the old design-bid-build standard.

While design-bid-build is still the traditional model on construction projects, new numbers tell you all you need to know:

- 82% of owner respondents said they’ve used or plan to use design-bid-build in the next five years, while 58% of owners said they’ve used or plan to use design-build

- Just over half of owners surveyed said design-bid-build usage would stay about the same over the next five years, while 32% predicted a decrease. Only 15% of owners predicted an increase in usage of the method

- 29% of owners said design-build adoption would stay the same while 67% predicted increased utilization

So what exactly is the difference between design-bid-build and its increasingly popular successor, design-build?

The Basics of a Construction Tradition: Design-Bid-Build

In design-bid-build construction, the owner and design team work together to develop the scope, program and design of the project before it goes out to bid. Then the general contractor, subcontractors and material suppliers build per the specified design.

The general approach is somewhat set in stone before the project begins. When adjustments are needed, each subcontractor or team has to decide how best to do so within the context of timeline, budget, materials and the surrounding processes. Even if they try their best, they often miss the mark on the most effective course corrections.

The main problem: each niche is incentivized to remain siloed. As a result, electricians don’t know what plumbers are doing, who don’t know what welders are doing–and none of them have substantial intel when an expectation changes either within one of the other niches or from the top down.

How Does Design-Build Differ from Traditional Models?

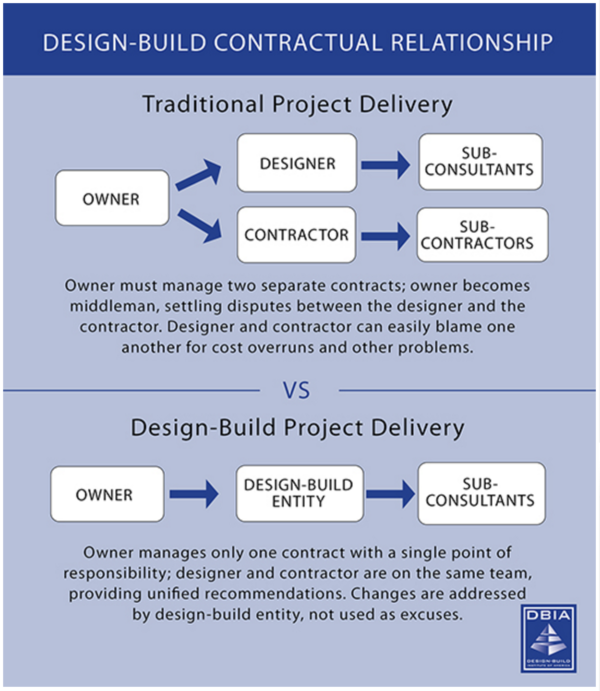

In direct opposition to the siloed approach, “Design-build is a method of project delivery in which one entity–the design-build team–works under a single contract with the project owner to provide design and construction services,” explains the Design-BuildInstitute of America (DBIA).

“One entity, one contract, one unified flow of work from initial concept through completion. Design-build is also known as design/construct and single-source responsibility.”

As such, the owner manages only one contract with a single point of responsibility. The designer and contractor work together from the beginning, as a team, providing unified project recommendations to fit the owner’s schedule and budget. Any changes are addressed by the entire team, leading to collaborative problem-solving and innovation, without as many excuses and blame-shifting.

While single-source contracting is the fundamental difference between design-buildand the old ways, equally important is the culture of collaboration inherent in the delivery model. This culture of transparency helps immeasurably not only in clearing up misunderstandings but in avoiding the blame-shifting and mistake-making that can prove enormously costly down the road. It puts everyone on the same page, giving all the opportunity to make themselves heard and get what they need to provide the most successful contributions to the project.

The Benefits of Design-Build

Design-build yields quite a few benefits to the project site, owner, team and the final product.

Increased Project Speed

Owners routinely identify “delivery schedule” as the most significant influence of project delivery method selection, which explains why design-build is quickly overtaking its traditional cousin. Owners want work done on time and the quicker, the better.

“In design-bid-build, valuable time is consumed by the bidding process and by the creation and management of multiple contracts for each of the entities involved,” explains Water Online. “With design-build, there is typically no bidding process, and with only one contract, the process is significantly streamlined.”

Plus, “Construction time itself is also shorter with design-build, as all engineers, architects and builders are on one team.” As such, “building on one part of the project can commence while the engineers and architects are still nailing down the details of another part.”

Just take a look at one shining example of design-build in action. According to American City & Country, “On Aug. 1, 2007, the I-35W Bridge over the Mississippi River collapsed. Thirteen months later, on September 18, 2008, the first cars rolled across the newly constructed bridge. The Minnesota Department of Transportation (MnDOT) used design-build to complete the construction.” The magazine continues, “The state was able to save time by overlapping design and construction activities. The state avoided an estimated $400,000 a day from lost revenue and the costs of detouring traffic caused by the downed bridge.”

Reduced Costs

Initial cost is always a critical factor in project delivery selection. Design-build has a total project budget established at the beginning of the project–usually includes a fixed design fee and a tight implementation budget or a guaranteed maximum price (GMP). Establishing an accurate budget at the beginning of the project eliminates last minute surprises.

The research shows that alternative delivery methods provide a greater chance of meeting the initial budget than does design-bid-build. While design-build might look like more money up front, the cost savings in the long-run can be substantially more than other delivery models.

More Collaboration = Less Risk and Mistakes

Due to the nature of design-build, everyone is working for one common project goal. In a traditional design-bid-build model, on the other hand, there’s a strong tendency for separate trades and teams to work on just what’s in their own best interest. While it’s hard to blame them since the separate contract model makes it difficult to work any other way, the research is very clear; this leads to disconnection, miscommunication and error.

On the other hand, the collaborative process of the design-build approach utilizes and encourages teamwork, develops deeper levels of cooperation, stimulates information sharing, enhances transparent communication between project members and improves the overall quality and project completion.

It creates greater accountability in several ways:

- There are far fewer “places to hide” during the construction process because everyone is on the same page

- It offers more avenues to air grievances and adjust plans on an ongoing basis

- The smoother workflow and closer connection creates a more positive and supportive working environment

There are many more emerging benefits of a design-build model. If there are opportunities for your company to start implementing the model on a new project, you might want to consider getting to the basics first.

How to Get Started Using Design-Build

It’s important to note from the get-go that not every project is right for design-build. Ultimately, the chosen project delivery method is what’s right for the owner and it’s their choice in the end. If you’re struggling to figure it out, here’s a useful evaluation sheet to determine which project delivery method is right for your project. If you want to learn more about the pros and cons of all the major delivery methods in construction, we’ve also composed a handy guide, “The Ultimate Guide to Choosing the Best Project Delivery Method.”

If you find that design-build is right for you as an owner or contractor, you can get started with these critical steps:

Hire the Right Firm

Hiring the right team is an owner’s first essential step in getting started with design-build. Even in the procurement plan, the process should be based in collaboration and other fundamental values of design-build–after all, it is the chosen delivery method on the project and it should be incorporated throughout every aspect of the project.

Therefore, using a competitive procurement process, an owner should consider the following key aspects to hiring the right firm for a design-build project:

- A clear selection and evaluation process

- A selection process that is transparent and collaborative

- Evaluations that value both the price and technical expertise presented

Set Up Project Guidelines

The right contract is essential for design-build to truly work. The single contract used should be fair, balanced and clear, and should foster team-wide collaboration throughout the entire design and construction process. Usually, contractors are responsible for writing the contract, considering they will be managing both design and construction. Specifically, the agreement between the owner and design-builder should address the unique characteristics and processes of design-build.

Train Your Team

It’s critically important to ensure all design-build team members are educated and trained in the process and know the differences between it and other delivery systems. If you don’t have the right skills, hire staff and people who do; it’s okay to rely on others for expertise you lack. Bottom line: Make sure someone on your team has what it takes. No shooting in the dark.

Get the Right Tools

Even with the right project contract, team and guidelines in place, you don’t necessarily have all the tools to complete a successful design-build project. Having access to the right digital tools–such as BIM collaboration software–throughout the design and construction process will enhance coordination and communication throughout the project.

Take Small Steps Towards Design-Build Today

Design-bid isn’t going away any time soon–it’s only growing in popularity. If you’re an owner or firm new to design-build, it will take time to master and excel in a new process. If you can do so successfully, projects can benefit enormously.

Need more resources and information? Check out the leading source for all things design-build, the Design-Build Institute of America (DBIA). There, you’ll find a wealth of tools and information to help you move into this next phase of your building business.